HiCAD, ISD Group's 2D/3D CAD software, enables facade constructors to engineer more efficiently. The package combines the mechanical aspect (the development and production of facades) with the architectural aspect (their application). Willem van Kreij, Sales Consultant at ISD Group, explains what this combination makes so powerful for facade engineers.

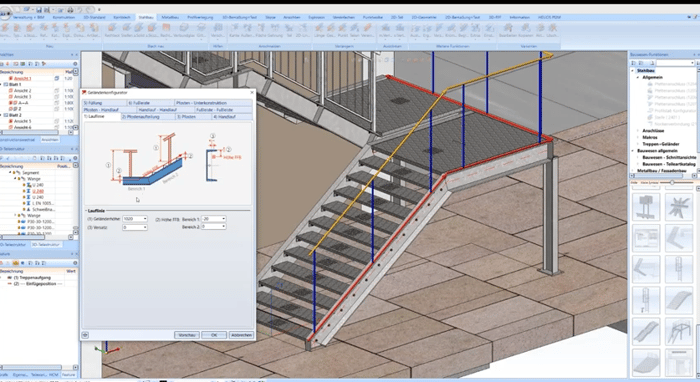

ISD Group develops CAD and PDM software. "Our roots (since 1977) lie in mechanical engineering," starts Van Kreij. "This sector shows a great deal of affinity with facade construction. After all, 90% of the facade engineers design and produce their own facades. HiCAD was developed from this perspective, a software programme that offers plenty of room for both the mechanical engineering aspect and the building physics. The software is ideally suited for modelling aluminium profile systems and sheet metal in all shapes and sizes, as well as for steel engineering (construction, stairs, fences, platforms).

Managing production

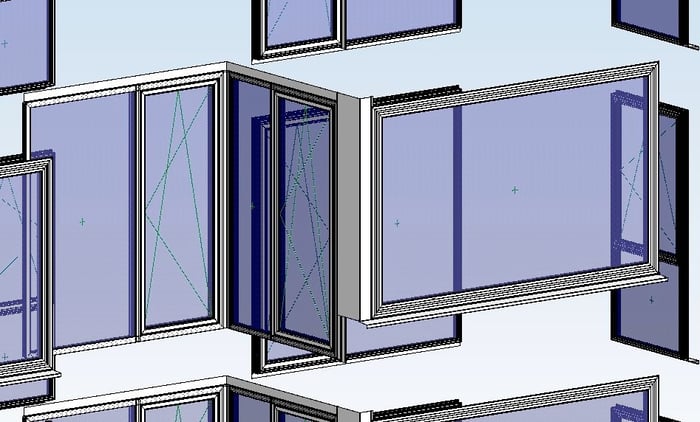

According to Van Kreij, facade engineers are often looking for systems to improve the engineering process. "Clients, contractors and architects mainly steer towards Revit, while subcontractors, such as facade engineers, have an entirely different requirement: the automated control of production. This is not optimal in Revit. In HiCAD it is optimised. Users of HiCAD can convert file formats such as IFC, DWG/DXF, STEP, etc. into a 3D model. In combination with LogiKal, it is possible to design windows, doors, window frames and curtain walls, including the necessary settings. HiCAD then automatically generates layouts, production and assembly drawings, as well as bills of materials and saw lists for controlling production. A direct connection to LogiKal also ensures that, if something is changed in one place, these changes are automatically synchronised/updated in HiCAD."

Complex shapes

Also (complex) curtain wall facades and element facades (ACP or other materials) can be engineered in HiCAD. "For the last one, there is even a special module where the IFC file is loaded and the software automatically recognises the grid lines. You can then design the cassettes in the software, apply the rear structure and let both ‘connect’ to each other. The library automatically inserts bars, nails, etc. with millimetre precision. When the model is ready, you generate an IFC or production files for the client, contractor or architect at the push of a button. In this way, everything remains within one software system. That makes all other CAD software unnecessary."

ISD Group attaches great value to service and support. Van Kreij: "We seek very consciously cooperation with our software users. After implementation, we provide after service and give (on-site) training. We are also constantly open to suggestions for possible improvements. These are ultimately either included in the standard software or implemented via API by our own programmers for customer-specific functionalities."

Fotografie%20Mike%20Rikken_Nijverdal_Bedrijfsfotograaf_ISD%20Benelux_HR-2368%20copyBEW_.jpg)